Unshakeable Seating Solutions

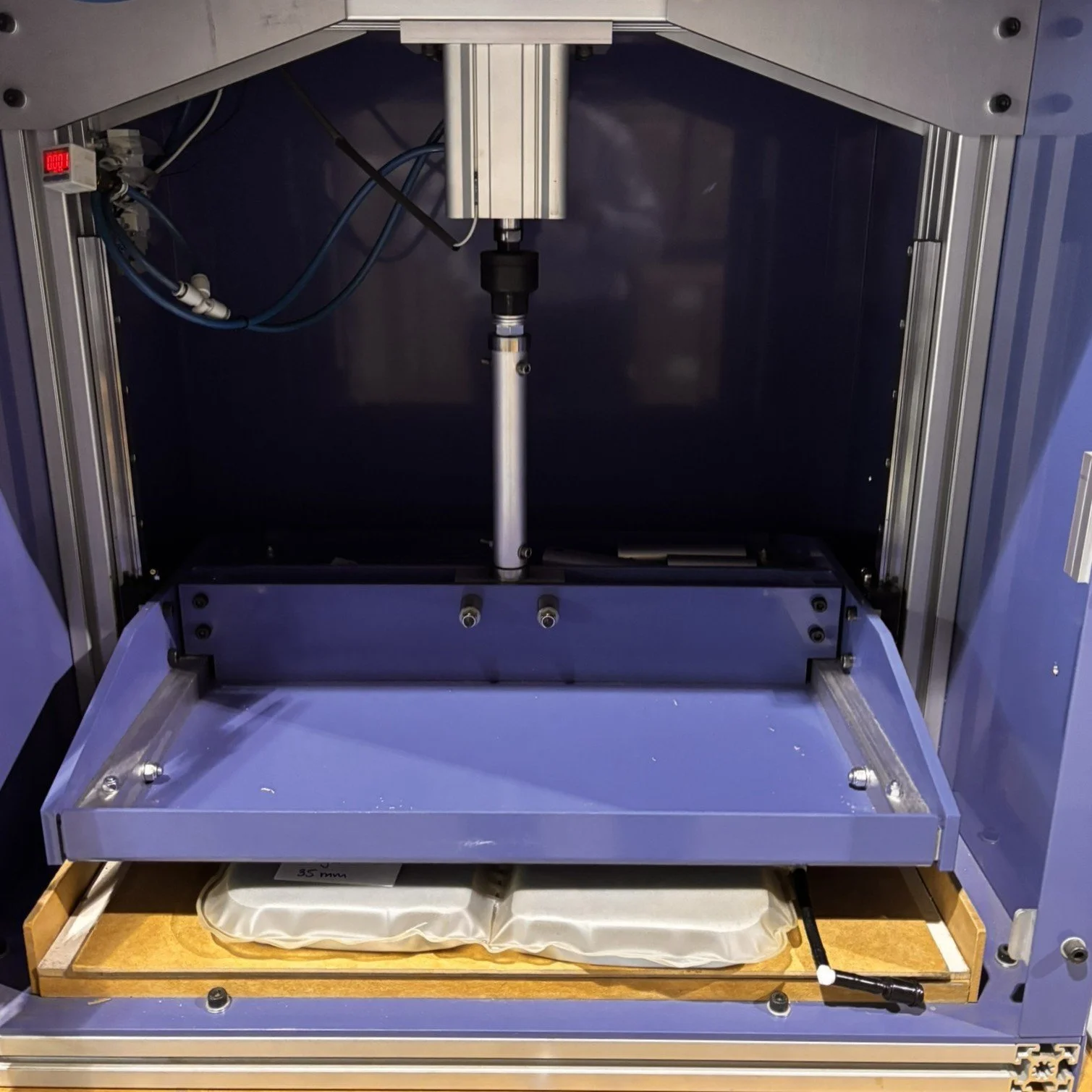

/Aircare press Testing

Why Our Testing Turns Good Ideas into Unshakeable Seating Solutions

When designing seating, a failed component isn’t just an annoying hiccup; it’s the kind of thing that eats into budgets, slows down production, and makes your brand reputation wobble. At AirCare Systems, our mission is to eliminate that risk by delivering components you can trust, backed by airtight reliability and proven durability.

How do we do that? By building reliability right into the DNA of our air cells. Our philosophy is that quality is engineered in from day one…and then we really go to town on testing. Not just ticking the “meets standard” box, but pushing our products far beyond what most people think is reasonable.

It All Starts with What We’re Made Of

Aircare Press Testing with the equivalent of 205kg

We only use top-grade thermoplastic polyurethane (see more about TPU here) for our air cells, because it is strong, flexible and doesn’t give up under pressure. Excellent material choice is only the first step; the real magic is in how we test that material.

The Tests That Separate “Good Enough” From “Unshakeable”

Because we actually enjoy pushing the limits, listed below are the extreme measures we have implemented that go far beyond industry standards:

1. Seam Integrity: The Heart of an Airtight Seal

Seams are where most of the action happens, so they’re also the most likely place for weakness. We like to give them some pretty tough challenges:

Weld Rip Analysis – When we tear it apart (literally), the TPU itself gives way before the weld does. That’s when we know the bond is stronger than the material. When looking closely, you’ll see a neat, shallow trench, which is the hallmark of a flawless weld.

45-Stone Endurance Chamber – Imagine sitting on a chair every day for more than a decade. That’s what we simulate by squashing our air cells for up to 120,000 cycles under a 45-stone load. The rule is simple: if it leaks, it fails. Ours don’t leak.

2. Extreme Load: The Forklift Trials

When we say “extreme,” we really mean it.

3-Ton Forklift Test – Yes, we actually drive a forklift over a fully inflated air cell. The requirement? It must come out intact and airtight. And it does, every time.

Forklift Scrubbing Test – Pressure is one thing, abrasion is another. This test shows our TPU can handle rough treatment without splitting or tearing. Toughness, proven in the most industrial way possible.

3. The Overnight Test: The Quiet but Crucial Check

After all the drama of forklifts and endurance chambers, the last test is deceptively simple. We inflate an air cell and leave it overnight. By morning, it either holds its seal, or it doesn’t. There’s no middle ground. Ours stay rock solid.

What This Means for You

All this testing isn’t just engineering theatre, but real value for chair designers and seating manufacturers:

Save Time & Money - Catching flaws avoids costly recalls, warranty headaches, and production delays.

Protect Your Brand - Your reputation is built on reliability. Using our seating air cells means your ergonomic seat performs as promised, year after year.

Why choose us as your ergonomic seating component supplier

At AirCare Systems, we don’t just promise durability; we can actually prove it. With science, with forklifts, with long nights in the lab. So, if you want to design an ergonomic chair, you can do it with absolute confidence in what’s inside.

Want to see the tests for yourself? Get in touch with AirCare Systems today and let’s build seating solutions that stand the test of time …and forklifts.